Dr. Panče Naumov's Research Team Develops First-of-its-Kind Woven Material Made Entirely from Flexible Organic Crystals

In an exclusive interaction during his busy lecture tour, we had the privilege of speaking with Dr. Panče Naumov, the pioneering mind behind a groundbreaking development in material science. At the Smart Materials Lab (SML) and the Center for Smart Engineering Materials (CSEM) at NYU Abu Dhabi, Dr. Naumov and his team have achieved a remarkable feat: creating the first-ever woven material made entirely from flexible organic crystals. This innovative textile, detailed in their paper “Woven Organic Crystals” published in Nature Communications, transforms one-dimensional crystals into strong, flexible two-dimensional structures. The material, up to 15 times stronger than the original crystals, also maintains its flexibility in extremely low temperatures, presenting vast potential for applications in flexible electronics and space exploration.

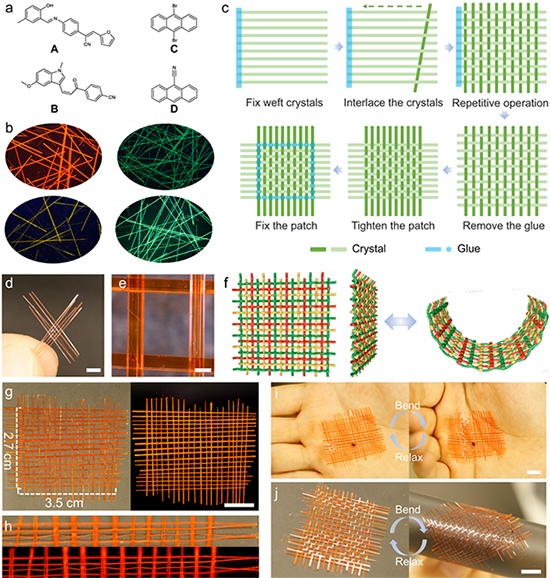

This research signifies a major shift in our understanding of organic crystals, traditionally considered stiff and brittle. The team’s method, which involves weaving the crystals into various textures like plain, twill, and satin, results in a fabric that is not only lightweight and mechanically robust but also thermally stable over a wide temperature range. This surpasses the performance of many conventional polymers and elastomers. Furthermore, the optical translucency of the material opens new avenues in optical computing, as demonstrated by the researchers’ success in using these woven crystals for simple logic functions. The project highlights the unexpected flexibility of organic crystals due to their weak intermolecular interactions, proving the immense potential of combining ancient weaving techniques with cutting-edge materials science.

Dr. Naumov, a figure of international repute in material science, has an illustrious academic and professional journey that spans several continents. From his early education in Macedonia to his Ph.D. in Japan, followed by tenures at esteemed institutions including the National Institute for Material Science and several universities in Japan, Dr. Naumov has amassed a wealth of experience. His significant role in establishing the chemistry department at NYU Abu Dhabi is a testament to his expertise in the field.

At the heart of Dr. Naumov’s research lies the exploration of smart materials. His lab’s work, reflected in numerous prestigious publications, covers a wide array of smart materials, including smart crystals and those relevant to petroleomics. These materials, characterized by their response to external stimuli such as light, heat, and mechanical force, possess unique properties including durability, self-repair, and adaptability. Dr. Naumov’s fascination with these materials stems from their ability to convert energy, drawing a parallel to the energy transduction fundamental to the first industrial revolution.

The innovation extends to the dynamic capabilities of these crystals. Their adaptability in response to external stimuli is a remarkable feature, showcasing the synergy between material properties and fundamental physical principles. This aspect of the research not only advances our understanding of smart materials but also highlights the significance of basic physical principles in contemporary scientific exploration.

Dr. Naumov pioneered the field of crystal adaptronics, where these organic crystals are explored, focusing on harnessing their adaptive nature, blending ordered structures with plastic-like flexibility. This approach could lead to materials with enhanced physical properties such as improved conductivity and optical transparency, offering an edge over traditional soft materials.

The application of ancient weaving techniques to these crystals has been a game-changer. Transforming elongated crystal structures into two-dimensional fabrics has significantly enhanced their mechanical stability and robustness. The weaving process itself, akin to creating cloth, transitions the material from a delicate structure to one that is both thin and flexible yet stronger.

Despite the advancements, challenges in scalability remain, particularly in selecting crystals of uniform size for weaving. Future automation could streamline this process, enhancing the practical application of this technology. The varying mechanical strengths of different weaving patterns, such as plain, twill, and satin, also reveal the potential for diverse applications based on the method of weaving. While the electrical conductivity of these materials is still an area of exploration, their mechanical resilience, especially in the satin weave, is noteworthy.

The potential applications of these woven organic crystals are particularly promising in fields like flexible electronics and space exploration. Their resilience against low temperatures and mechanical impacts, coupled with the elasticity enhanced by the cooperative interactions within the woven structure, is invaluable. The synthesis of these crystals, a collaborative effort with Jilin University in China, involves common chemical methods and has led to the creation of a diverse library of materials with varied fluorescent properties, enhancing their utility in various applications.

In conclusion, the development of woven organic crystal technology marks a significant milestone in material science. It challenges the conventional perception of crystals as rigid and inflexible, unveiling their potential as adaptable, compliant materials. This breakthrough not only broadens the prospects for their use in flexible electronics and other applications requiring compliant materials but also heralds a new era in material science. Here, the integration of flexibility and structure opens new frontiers for technological advancements, cementing the role of these innovative materials in the future of scientific and technological innovation.

Credit: Dr. Panče Naumov’s lab and Dr. Hongyu’s lab