Dr. Ignaas Jimidar harnesses friction to power tomorrow's self-charging devices

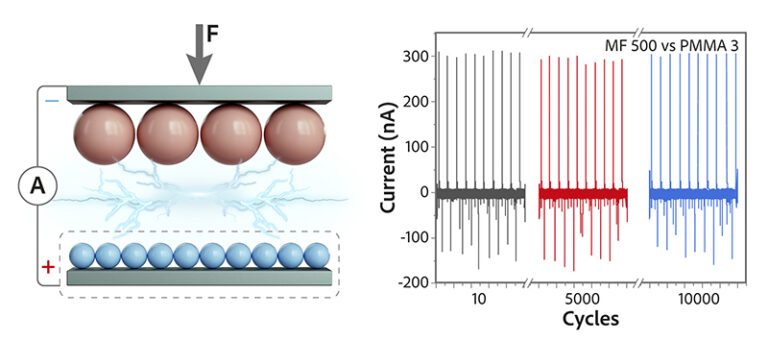

In a significant advancement for sustainable energy, scientists are harnessing electricity from friction using innovative triboelectric nanogenerators (TENGs). This technology captures energy from small scale motion when different surfaces interact. A key breakthrough involves using melamine-formaldehyde beads, whose unique physical properties enhance charge transfer. Dr. Ignaas Jimidar of Vrije Universiteit Brussel (VUB) recently published findings on February 5, 2025, in Small, detailing how surfaces covered with these carefully selected microscopic beads generate significant electrical charges through contact.

Dr. Jimidar’s research revealed intriguing patterns: larger beads tend to develop negative charges, while smaller ones acquire positive charges. By optimizing bead size and composition, the team improved energy generation efficiency without expensive components. While opening doors to applications like self-charging wearables, challenges in reliability and scalability remain. We spoke with Dr. Jimidar about his work.

The Origin Story

Q: What sparked your interest in harvesting electricity from tiny plastic beads?

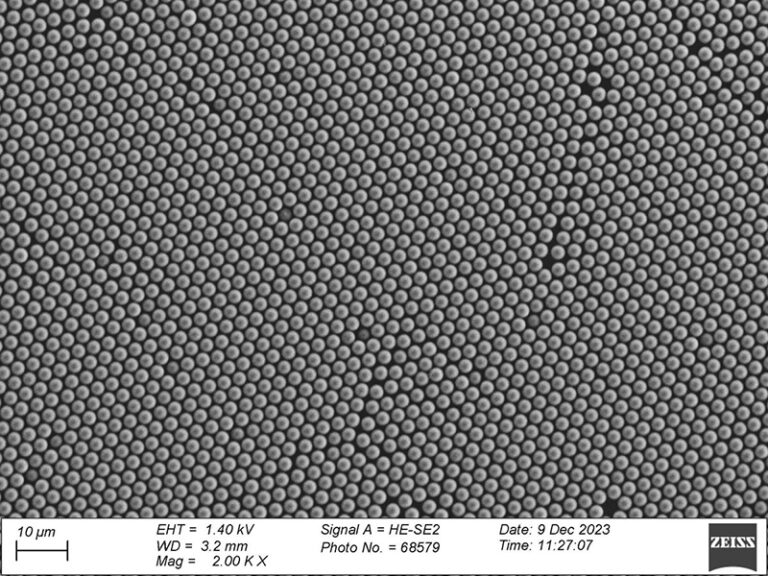

A: It originated from our focus on developing solvent-free assembly techniques for creating ordered microstructures sustainably. This dry approach is much faster—around 20 seconds—and scalable or automatable, unlike traditional wet methods requiring slow solvent evaporation. While exploring applications, we collaborated with TENG researchers at Riga Technical University and RMIT. We realized our particle structures inherently created the consistent topography needed for triboelectric surfaces, offering an alternative to expensive conventional methods like stamping or etching. It seemed a natural fit.

Q: Your academic path seems diverse. How did you arrive at working with these beads?

A: I started with mechanical engineering in Suriname, then pursued applied physics and fluid dynamics in the Netherlands. For my PhD, I shifted towards chemical engineering, somewhat stumbling into a project on powders and beads. The physics is fascinating; granular materials connect back to fluid dynamics, but at the microscopic scale of powders, surface forces dominate gravity, unlike with macroscopic marbles. Developing solvent-free assembly for these materials added another layer of interest.

Understanding the Science

Q: Can you simply explain how friction between these beads creates power?

A: It’s fundamentally the same static electricity we experience daily, like rubbing a balloon on hair—contact and friction cause charge transfer. Interestingly, the exact mechanism isn’t fully understood. Theories involve electron transfer, material transfer, or multiple simultaneous processes. Environmental factors like humidity significantly influence charging, adding complexity. Recent research is even challenging old assumptions; a Nature study showed that even chemically identical materials, like two pieces of silicone rubber contacted repeatedly, can develop opposite charges, likely due to subtle surface differences or contact asymmetries.

Q: Is the positive and negative charging random, or controllable?

A: There’s an element of randomness, particularly in identical material interactions where explaining why one surface trends positive and another negative over time remains difficult. You can even get charge patches on a single surface. However, careful material selection allows general control over charging behavior. But environmental sensitivity—humidity and temperature affecting charge development—is a major hurdle for real-world applications.

Q: Why specifically melamine-formaldehyde beads?

A: Honestly, they were readily available from our supplier initially! But scientifically, they work well because melamine-formaldehyde is exceptionally stiff and hard for a polymer. This stiffness enhances surface contact area when pressed against a softer material, significantly boosting the charging effect.

Q: Do quantum physics principles play a role?

A: Some researchers approach it from a quantum perspective, examining electron band states and potential electron trapping during contact. However, studying triboelectric effects is challenging because minute surface variations or factors like a thin water layer can drastically alter results, making it hard to isolate and confirm a single mechanism.

Q: How did discovering that bigger beads go negative and smaller ones positive shape your approach?

A: That finding directly informed our material selection strategy. To maximize charge generation, we realized we should pair materials with complementary properties: make the smaller beads from a stiffer material (to enhance positive charging) and the larger beads from a softer material (favoring negative charging). This combination amplifies the charge difference and potential, increasing power output.

Applications and Future Directions

Q: How close are self-powered wearables?

A: We’re not quite there. Key questions remain about material performance in varying conditions, long-term skin safety, sustainability, and crucially, durability. Consumers expect wearables to last years. My educated guess is perhaps five years until we see reliable integration into commercial wardrobe items. Translating lab results into robust consumer tech takes time.

Q: What might be the first commercial product using this tech?

A: Watches seem likely, potentially alongside smart clothing. Clothing offers unique opportunities due to natural movement-induced friction. Imagine fabric generating power for integrated heating elements when it’s cold. These applications seem closer than large-scale uses like harvesting energy from ocean waves, which is a longer-term vision.

Q: What’s the toughest hurdle to replacing batteries with TENGs?

A: Stability is definitely the biggest challenge, especially for powering larger loads consistently. TENGs can be efficient on a small scale, but ensuring reliable output under varying conditions for extended periods is the major obstacle preventing them from replacing conventional batteries for power-hungry applications. The technology is better suited for low-power uses where intermittent energy harvesting is acceptable.

Q: Where do you see this tech in 10 years?

A: I envision wider integration into computers and sensors rather than large-scale power generation. Self-powered sensors are a very promising path, as nearly all sensors need energy. We’ll likely see adoption in textiles, clothing, and watches. I’m more skeptical about powering homes or cities soon, as the current and voltage outputs are relatively low, making TENGs better suited for distributed, small-scale energy harvesting.

Technical Innovations

Q: How small are these beads?

A: We used beads ranging from about 10 micrometers down to 500 nanometers. That smaller end, half a micrometer, is much finer than a human hair, enabling the creation of effective micro-structured surfaces.

Q: What advantages did going solvent-free bring to your TENGs?

A: Speed and versatility were key. The dry assembly allowed extremely fast electrode creation across various particle types and sizes using consistent process parameters. This consistency across different materials was a significant benefit, avoiding constant recalibration.

Q: How do you control 3D stacking without solvents?

A: Honestly, controlled 3D stacking using dry methods is still an active challenge we’re exploring. Preliminary work suggests success is highly dependent on particle type and size.

Q: How sustainable is this technology?

A: Our solvent-free assembly process is a definite sustainability win by eliminating solvents during device fabrication. While the beads themselves are often made using solvents, research into greener production methods like droplet microfluidics is ongoing. Compared to energy-intensive conventional methods for creating structured surfaces (like etching), our technique is more sustainable, an advantage applicable beyond TENGs to fields like bioanalysis.

Q: What’s the next big step toward real-world application?

A: Gaining a deeper fundamental understanding of the triboelectric charging mechanisms, particularly regarding stability under varying environmental conditions. Answering how electrical output changes with the environment is critical for moving from lab demonstrations to practical devices.

Q: Did anything surprise you during this research?

A: It was surprising that despite extensive study of triboelectric effects, using structured microbead layers for energy generation hadn’t really been investigated before. The effectiveness of these tiny structured beads seemed straightforward in retrospect, but it was an unexplored avenue.

Conclusion

Research into microsphere-based TENGs, particularly using solvent-free assembly, highlights a promising path toward efficient and sustainable energy harvesting. While significant challenges related to environmental stability and material optimization remain, continued investigation into the fundamental science of triboelectric charging is crucial. Through collaboration and innovation, friction-powered wearables and self-powered sensors may soon transition from laboratory concepts to everyday realities.