Major Breakthrough in Synthetic Spider Silk Fabrication Made by Dr. Fuzhong Zhang

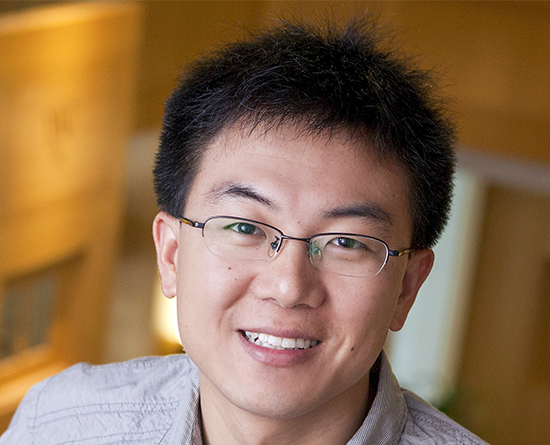

Dr. Fuzhong Zhang, a professor of energy, environmental, and chemical engineering at Washington University in St. Louis McKelvey School of Engineering, recently made a major breakthrough in synthetic spider silk fabrication. By using genetically engineered mussel foot proteins, Dr. Zhang created new spider silk recombinant proteins, called bi-terminal Mfp fused silks (btMSilks), which have achieved an 8-fold increase in bioproduction yield with improved strength and toughness. This result was recently published in Nature Communications.

We are honored to be able to speak with Dr. Zhang to learn about this quantum leap breakthrough in synthetic spider silk fabrication.

Dr. Zhang graduated from Peking University and majored in Chemistry. Afterwards, he went to the University of Toronto for his PhD. He completed his postgraduate studies at UC Berkeley in 2012. At Berkeley, his research was centered on engineering bacteria to convert cheap sugars into biofuels.

While at the University of Washington, Dr. Zhang one day read an article in C&E News about the extraordinary mechanical properties of spider silk fibers (a unique combination of high strength, high toughness, and lightweight) and difficulties in scalable production of spider silk. Many researchers from around the world have tried to produce synthetic spider silk in various alternative species, including bacterial and yeast, but failed to generate good results, mainly because spider silk is a special protein which has an extremely large and highly repetitive protein sequence. Microorganisms usually have difficulties in synthesizing such large quantities of repetitive proteins. Reading that, he realized that he can potentially solve this problem using his synthetic biology expertise. Since then he spent the next few years developing multiple strategies to produce synthetic spider silk fibers using engineered bacteria.

In 2018 Dr. Zhang published a research paper on production of spider silk protein using engineered bacterial Escherichia coli. It was demonstrated that, for the very first time, synthetic silk fibers made from microbes can be as good as natural fibers made by spiders. Later, he engineered the silk protein to further improve fiber strength. His group designed a modified silk protein with ⅓ of the original spider silk protein sequence replaced, and the resulting fiber was even stronger and tougher than some natural spider silks. This is how his research differs from other research teams and yields much better results.

The recent research results solved the production problem by reaching eight grams of fiber material from one liter of bacterial culture. Large molecular sequences are not very stable genetically; it is not easy for any microorganism to produce a lot of repetitive proteins; the longer the protein sequence, the higher the probability of mutation. While looking for different strategies to solve this problem, Dr. Zhang realized that it may be possible to produce strong fibers from relative small proteins if proteins can interact with each other at their ends, which can be achieved by interacting disordered proteins.

Disordered proteins are preferred for this purpose because they do not have protein folding issues. One such interacting disordered protein is mussel foot protein (Mfp). His team showed that adding Mfp to both ends of a silk protein not only improves the strength of the resulting fibers, but it also improves protein bioproduction yield. Dr. Zhang will continue to develop better protein sequences with better properties. This will pave the way for long-term development because we need to find sustainable, biodegradable fabrics to replace petroleum-derived fiber materials like nylon and polyester according to Dr. Zhang.

Dr. Zhang is interested in working with specialty industries such as sports, medical, and aerospace. Dr. Zhang believes that his lab’s technology can make very rapid innovation in sustainable fabrics because it can take as short as two weeks to design, build, and test one idea about fiber engineering.

Dr. Zhang believes synthetic silk has great potential. Other than light weight attributes, its strength and durability would be great for other industrial uses. Many new functions can potentially be incorporated into their fibers using their technology, resulting in renewable, strong, biodegradable and functional materials.