Nature Inspired Biomimicry Design by Lilian van Daal

By embracing the biomimicry philosophy, product designer Lilian van Daal studies nanoscale details in nature and explores innovative technologies and materials to produce products that imitates nature. By doing so, she streamlines the production methods while achieving environmental sustainability. For her, nature is the best teacher because species have spent millions or even billions of years evolving toward perfection on earth. The ones that have survived are equipped with the most efficient structures and functionalities.

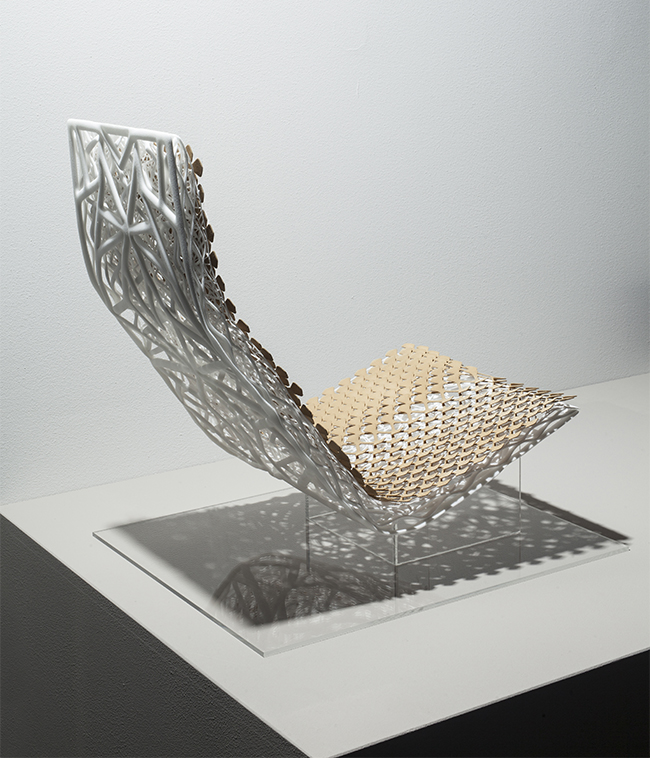

Lilian’s 3D-printed soft seat, Biomimicry, is her initial approach to taking materials from plant cell structures. By using 3D printing to imitate geometric shapes, she is able to build a breathable soft seat with support and comfort just from one single material. Contrary to the conventional industry production methods using chemicals to glue various materials together, her soft seat proves that it can provide the same functionalities while making recycling possible. This award-winning chair was acquired by NEOM in Saudi Arabia.

We are thrilled to get hold of Lilian and learn about her design philosophy and recent work. We hope her story will inspire you to also take inspiration from the greatest designer – nature.

Q: You are at the forefront of creating innovative products by mimicking nature through science, technology, and materials. Your designs have greatly influenced some industries. First of all, we would like to learn more about your background and training that lead you on such a marvelous path.

A: First of all, thank you for your compliments. I’m very happy that my work inspires people and influences the industry. That’s my goal!

In 2010 I graduated from the Technical University where I studied Industrial Design for four years. I mainly developed a lot of technical skills like 3D modeling and material knowledge. But in the end, I still didn’t feel I was a designer with a vision and mission.

I started working at an Industrial design studio where I worked on a large variety of projects in the design field. During this work, I did a Postgraduate Course in Industrial Design at the Royal Academy of Art in The Hague. This is where I started to work on my vision as a designer, the why and how of my work.

As a designer, you constantly create and produce new products. In terms of sustainability, this didn’t feel right anymore. If we create new stuff, we have to do it the right way. We have to think about the whole lifecycle of a product. Where does it come from and where does it go afterward? I learned about biomimicry and did some courses. I immediately felt extremely connected with this philosophy. I always had a weakness for biology and combining creating products with biology felt so good!

Q: What is your design philosophy?

A: I work from the biomimicry philosophy. Biomimicry (literally: imitation of the living) aims to take inspiration from natural selection solutions adopted by nature and translate the principles to human engineering. The biomimicry approach aims to favor “choices” tested by nature which had millions of years to understand what works best and what doesn’t. Designs following biometrics will ultimately allow human production to be more efficient, resilient, and sustainable.

The central idea is that nature has already fixed many problems society is facing. Animals, plants, and microorganisms are experienced engineers. They know what works, what’s appropriate, and most importantly, what lasts on Earth. The main belief of the biomimicry approach is that after 3.8 billion years of research and development, what did not work is now a fossil, and what is around us today is the secret to survival.

Q: Which areas of nature inspire you the most and what types of products do you conceive from these inspirations?

A: Actually, there is no specific area that inspires me the most. What I always do is look at nature in its smallest detail. I love working with my microscope and you can learn a lot from the structures and the material they are made of. It really depends on what my goal is, and what I want to achieve with a product. Do I want to create a very rigid material or product or something with comfort and flexibility? At the moment, I work a lot on furniture pieces such as sofas, tables, and lighting. But also a whole interior for a coworking space.

Q: Please tell us more about your 3D-printed soft seat, Biomimicry; the ideas and technology behind this product.

A: With this seat, I wanted to show a new perspective on the production of soft seating. Nowadays, couches are made of various materials, such as wood, metals, plastics, foam, textiles, etc. All of these are, most of the time, glued together. This means these products are impossible to recycle. I wanted to show we could do it differently and started to ask myself: ‘How would nature build a comfortable seat, such as a couch, with all these different functionalities?’

I found out that in nature, a single material is built with different structures. This is how functionalities are created. With 3D printing, we are able to replicate these structures including their smallest details. So I modeled a lot of structures I’ve found in nature and after 3D printing them from one single material, I could see what functionality fits what kind of structure.

The end product results in a comfortable soft seat that fits all the requirements but from one single material which can be fully recycled.

Q: Please tell us more about your other designs, Sweden (Volvo chair) and Stroncq.

A: Gladly, they are listed as follows:

Shapes of Sweden (Volvo chair)

The project ‘Shapes of Sweden’ was developed for the Volvo Design Challenge which I won in 2015. For this challenge, I dived into the brand proposition of Volvo and the Swedish environment. I merged the essences of these together with the biomimicry approach. My goal was to create an efficient car seat (based on my biomimicry soft seat project) with its essential functions; flexibility, resilience, and stability from a locally resourced and abundant material. For this, I did extensive material research with biobased materials which are abundant in Swedish nature, such as pine wood and pine resin, and tried to make these materials 3D printable. Nature was also the source of the design: I used structures for each functionality that were inspired by Swedish nature, such as tree branches, leaf vein structures, pine cone scales, etc.

JURY COMMENT from VOLVO DESIGN CHALLENGE:

‘Lilian van Daal was able to capture three topical developments in her Shapes of Sweden: biomimicry (an approach to innovation that seeks sustainable solutions to human challenges by emulating nature’s time-tested patterns and strategies), 3D printing, and the use of natural materials. Not only does the concept have a clear vision of the future but also it shows its strong relation with the Volvo brand. Her work is innovative, and aesthetic and provides perspective for the industry.’

Stroncq

Stroncq is an ecological and biodegradable embankment reinforcement tile inspired by the strength of the root structure of plants. A project in collaboration with Omlab.

Inspiration from nature

What can nature and its smallest life forms teach us? These small life forms are the starting point of my research.

How can we create the strongest possible embankment reinforcement by imitating natural principles? And how can we create something that will eventually be taken over by real nature? The project is a symbiosis of design, biology, material, and technology.

Plant roots are the most efficient embankment reinforcement we can think of. In our “man-made” world, we are sometimes looking for fast solutions. This embankment reinforcement tile is made from a 3D printable, ecological material developed by Omlab, with 98% residual flows from sewage and drinking water treatment.

Lime in the 3D-print paste counteracts the acidification of the soil. Seeds can be added to the paste and after a while, the root structure of plants will take over the strength of the biodegradable tile.

This project was a showcase for a call for product ideas: Maacq Waar(de), a co-op of AquaMinerals and Omlab. To show the great potential of the material and technology, the embankment reinforcement tile forms the seat of Stroncq. A seating object that shows the strength of the material.

Q: If you don’t mind, please share with us your current project based on spiderweb construction.

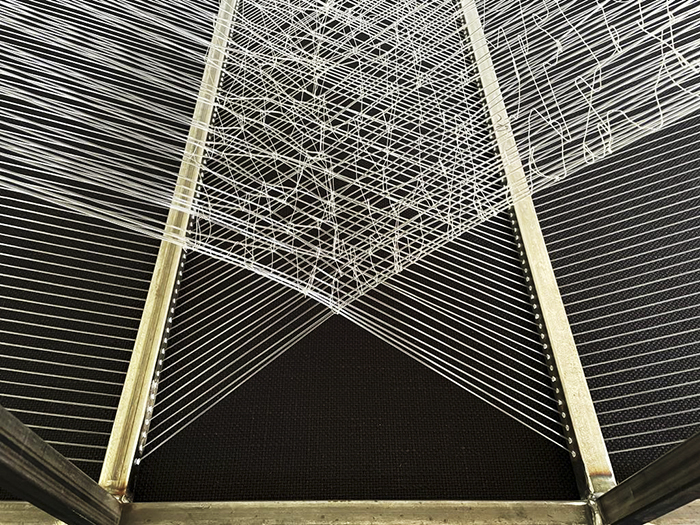

A: Diving into natural structures and their functionalities have intrigued me since my first project. Spiders, silks, and webs have survived and prospered for millions of years, making them an evolutionary success. They have optimized and adapted their lightweight and high-performance web architecture by providing housing, protection, and an efficient tool for catching prey due to its strength, toughness, elasticity, and robustness. I am now investigating the different ways they weave their web and transforming this into a lightweight and high-performance lounge piece developed with the use of as little material as possible.

Q: Please tell us more about “Structure Library”?

A: Structure Library is a project which was set up by two Dutch architects (now called: Biomi) and a whole team of other professionals of which I was a part. The idea was to set up an open-source library with (nano) structures from nature and their functionalities which can be used by designers/architects to improve their designs.

Q: Is there anything else you would like to tell our readers?

A: I love to inspire people with my work and show new perspectives on the way we design and produce. I am always open to new projects and nice collaborations. So please don’t hesitate to contact me and let’s share our knowledge!

*****