Tatami Reimagined: The Creative Journey of the Tatami ReFab Project

The Tatami ReFab Project series, originating from Japan, utilizes recycled tatami as a foundation and combines it with 3D printing technology to create modern and aesthetically appealing furniture. With its rustic and minimalist patterns, as well as innovative designs, it stood out at this year’s Milan Furniture Fair’s “SaloneSatellite” exhibition, winning the first prize.

The project acknowledges the historical significance and cultural value of tatami mats, which have been an integral part of Japanese living environments for centuries. It seeks to bridge the gap between traditional and modern lifestyles by showcasing the versatility and adaptability of tatami in today’s world.

By incorporating biodegradable plastics and other sustainable materials, the Tatami ReFab Project also aims to promote environmentally friendly practices while addressing the challenges of waste and resource consumption. Additionally, the use of 3D printing technology allows for creative and intricate designs, giving a fresh and unique aesthetic to the furniture pieces.

We are thrilled to be able to interview the HONOKA Studio, the design team behind the Tatami ReFab Project. In the following conversation, we are given not only a thorough introduction but also a sense of the challenges they encountered during the design process.

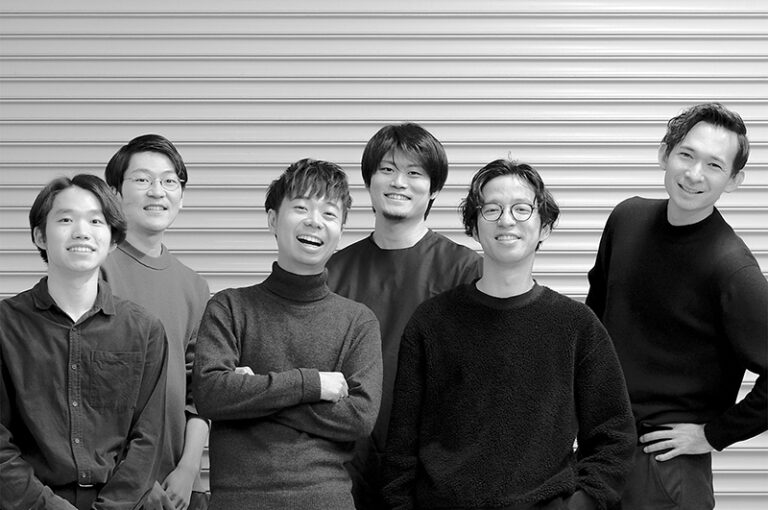

Q: Congratulations on the Tatami ReFab Project winning the first prize of the prestigious SaloneSatellite 2023. First of all, please introduce us to the designers who were involved in this project and their backgrounds.

A: Thank you! HONOKA consists of six product designers, including in-house and freelance designers.

Members are: James Kaoru Bury, Kazuki Fujiwara, Moritaka Tochigi, Ryo Suzuki, Shinnosuke Harada, and Shoichi Yokoyama.

We all have professional experience in the product design field, and have worked in Japanese in-house companies such as Toyota, Yamaha, TOTO, Epson, and Casio.

Q: Please tell us what the Tatami ReFab Project is and the designs for this project.

A: Tatami mats, which have been used in Japanese living environments for centuries, are made from plants that are fragrant and have the ability to adjust humidity and reduce odors.

The “TATAMI ReFAB PROJECT” is a project that re-embed Tatami into modern life using 3D printing technology. We design furniture from material made of recycled tatami with biodegradable plastic.

We will continue to appeal the beauty of tatami to the next generation.

The following are details of the “Tatami ReFab Project:

. SORI/MUKURI|Designer:RYO SUZUKI

SORI and MUKURI are knitted tatami-resin furniture. They are traditional Japanese shapes and textures refabricated through 3D printing. The unique knitted structure has a moderate transparency which changes its expression by the angle at which it is viewed.

. CHIGUSA | Designer: SHOICHI YOKOYAMA

Based on the motif of the traditional Japanese “Sen-suji” pattern, this stool combines multiple 3D printed parts.The elastic and durable tatami-mixed resin printed in vertical pattern creates a resilient sitting experience.

. TABA|Designer:SHINNOSUKE HARADA

Lighting designed from the motif of bundled grass. The plant-like shape was made by dripping the 3D printed material. Tatami-mixed resin diffuses the light, while the light spills out through the gaps of the branches.

. TACHIWAKI|Designer:JAMES KAORU BURY

Self-standing basin in which the body is made of multiple stripes, inspired by the Japanese traditional “Tachiwaki” pattern, used in Japanese Kimono. This pattern is created by controlling the purging speed of the 3D printer, allowing to create an unique expression which is new to the bathroom industry.

. YOCELL|Designer:MORITAKA TOCHIGI

Stool designed from the motif of traditional Japanese “Asanoha” pattern. Taking advantage of the 3D printer’s layer marks, unique expressions are created by combining them in different directions.

. AMI|Designer:KAZUKI FUJIWARA

Stool created by refabricating the Japanese 2D weaving expressions in a 3D form. The shapes were created by dripping 3D printed resin from air, creating a natural expression. The new weaving method and the color gradation allows it to change its expression depending on the angle at which it is viewed.

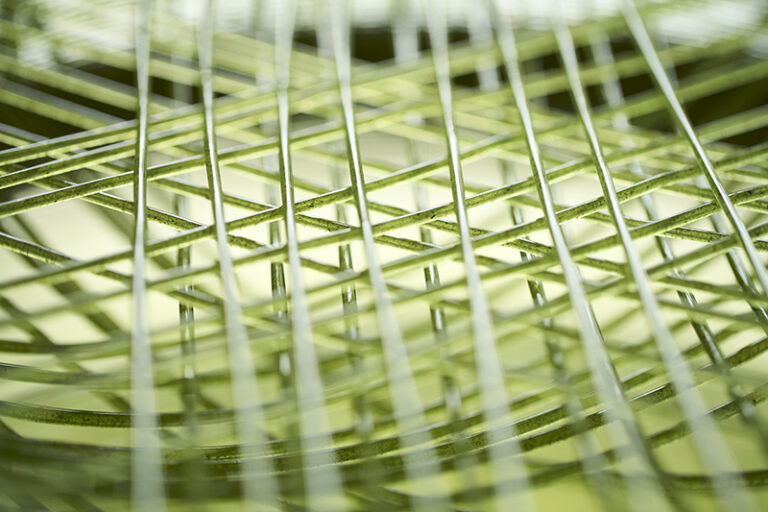

. KOHSHI|Designers:SHINNOSUKE HARADA / MORITAKA TOCHIGI

The lattice-like vase, reminiscent of Japanese architecture, allows plants to be inserted at any angle or position like the Ikebana (Japanese flower arrangement) .

Q: Please take us step-by-step in making this design into reality, including the 3D technology you employed.

A: The process for bringing this design to life involves several steps. Firstly, discarded tatami mats and igusa materials are collected. These materials are then ground, powdered, and combined with a biodegradable resin called cellulose acetate, resulting in the development of a new original material. Next, new manufacturing methods for 3D printing are researched, including layering, hanging, and changing the extrusion amount. Finally, original works are created using these techniques to bring the design to fruition.

Q: What functionality do your designs provide and the challenges you have faced?

A: We focused on creating a material that takes advantage of the unique aroma, good texture, and moisture regulation and deodorizing capabilities of tatami.

However, we have taken only one step for this, since the functionality of our material is still lower compared to normal tatami. We will continue experimenting to enhance the functionality of this material.

We have reconstructed the traditional Japanese craft techniques, and re-expressed them using 3D printing technology.

This was not easy, since we re-fabricated the traditional crafts using the 3D printer, and the settings of the printer needed to be just right, and we took weeks to get this right.

We adjusted the 3D data, the g-code, which consists of the XYZ movement of the printer, its speed and purging amount, the temperature of the nozzle, etc.

Q: What are your inspirational sources for these designs?

A: Our main source of inspiration is traditional Japanese crafts, patterns, and culture.

We believe that preserving and celebrating these aspects of Japanese heritage is very important.

By incorporating elements of traditional Japanese crafts and motifs, we hope to promote a deeper appreciation of the country’s rich cultural history and inspire new generations of artists and designers.

HONOKA is committed to pushing the boundaries of design and exploring new possibilities for sustainable, eco-friendly products.

Q: Please introduce your design studio and its speciality.

A: HONOKA is a design laboratory created by a group of product designers who specialize in researching and utilizing advanced manufacturing methods such as 3D printing.

Our main goal is to create innovative and sustainable products that incorporate the soft nuances of natural materials, experimenting with texture, aroma, and chromatics to achieve unique and compelling designs. By utilizing cutting-edge technology, HONOKA aims to explore new possibilities in product design and manufacturing, bringing new life to traditional craft techniques and materials.

Q: If you don’t mind, please tell us about your current/future projects.

A: As part of the “TATAMI ReFAB PROJECT” activities:

・The materials and designs presented at this time are prototypes. We will continue to develop materials that allow people to feel the benefits of tatami and igusa, and also work on product development.

・Through our activities, we learned that about 40% of the igusa (rush grass) used in tatami production is discarded. We will explore sustainable ways of using these materials, in addition to the method of mixing them with biodegradable resin.

・We view the decrease in igusa farmers and tatami craftsmen as a serious problem. We aim to contribute to the industry and revitalize it through our activities, as we strive to uphold the tatami culture and traditions.

As the design lab “HONOKA”:

・We will continue to research, develop, and present products that offer the attractiveness of various materials including discarded materials, through their texture, aroma, color, and more, without being limited to tatami materials or 3D printing technology.

・As we have received significant attention from the Japanese media, we plan to hold an exhibition in Japan.

Q: Is there anything else you would like to tell our readers?

A: We warmly welcome collaboration requests in the areas of material development, design, and other related fields. For further details, please visit our website at https://honoka-lab.jp.

*****

We have great admiration for the Tatami ReFab Project in its exploration of new technologies, materials, and design approaches. We hope that they will continue to push boundaries, attract attention, and maintain their position as pioneers in the field of sustainable furniture design.